Preventive Maintenance

Transformer and control following a recondition

Preventive Maintenance is gathering information about your equipment to determine its running condition. This information allows you to make a decision as to whether the equipment needs attention or is running properly.

Preventive Maintenance is an important aspect of your process that keeps your plant running and you making money. Being proactive about maintenance can reduce repair costs by finding problems present in your equipment before they become a more costly catastrophic failure.

A common misconception of preventive maintenance is that you need to shut down in order to perform the task. This is only true in some cases. Some types of maintenance, such as Infrared Scanning and Vibration Analysis, actually require the unit to be in operation to take the measurements.

At Spina Enterprises, your switchgear, machines, and AC and DC motors may undergo a number of different processes to ensure their smooth operation. Here are some of the techniques your equipment may undergo to keep your plant up and running at peak efficiency:

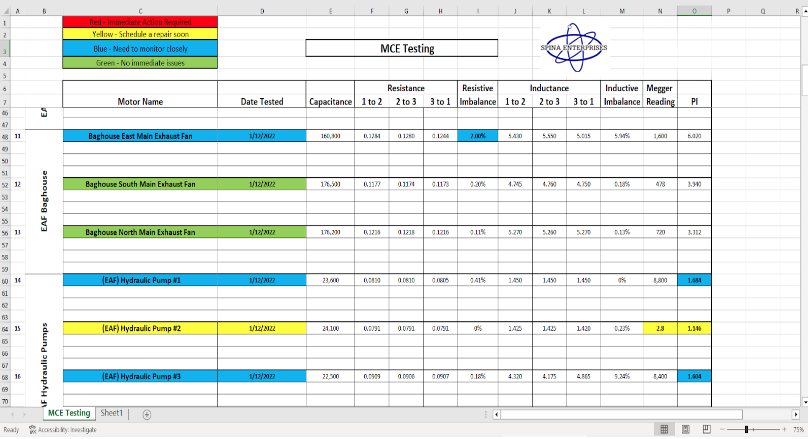

Preventive Maintenance Chart

| Technique | AC or DC Motors | Generators | Switchgear Units | In our Shop | On-site |

|---|---|---|---|---|---|

| Advanced Cleaning: Dry Ice Blasting | X | X | X | X | |

| Transformer Winding and Oil Testing | X | X | X | ||

| Electric Motor Testing / Brush Replacement | X | X | X | X | |

| Infrared Scanning | X | X | X | X | |

| Laser Alignment | X | X | X | ||

| Primary Injection Testing | X | X | X | ||

| Vibration Analysis | X | X | X | X | |

| MCE Circuit Testing and Analysis | X | X | X | X |

Motor Circuit Testing and Analysis

A simple test using an MCE (Motor Circuit Evaluation) machine can let us know what is going on inside your motor without removal or disassembly.

Testing can be performed on AC or DC Motors, including wound rotor and Synchronous.

Readings can normally be taken at the controls without disconnecting leads at the motor.

MCE testing offers a major benefit to preventive maintenance by reducing unforeseen failures, such as:

- Failure of insulation between the winding and the core

- Winding failure phase to phase

- Failure in a stator winding at the connection

- Winding failure to ground

- Failure of conductors leading to the motor

- Winding imperfections with AC and DC Motors

Our latest, state-of-the-art equipment provides clear and readable reports. They are even color coded to take the guesswork out of preventative maintenance. This technology has come a long way in saving time and ensuring accuracy in preventive maintenance for motors.

Transformer Electrical and Oil Testing

Spina Enterprises can test transformers in our facility or on-site. Resistance testing helps determine the current condition of the windings. The turn-to-turn ratio makes a comparison between the primary and secondary winding.

Oil testing can also be a huge indicator of the windings’ condition. The presence of certain gasses provides information to help determine actions (if any) that are needed to maintain operation.

Drawing an Oil Sample from a transformer on site

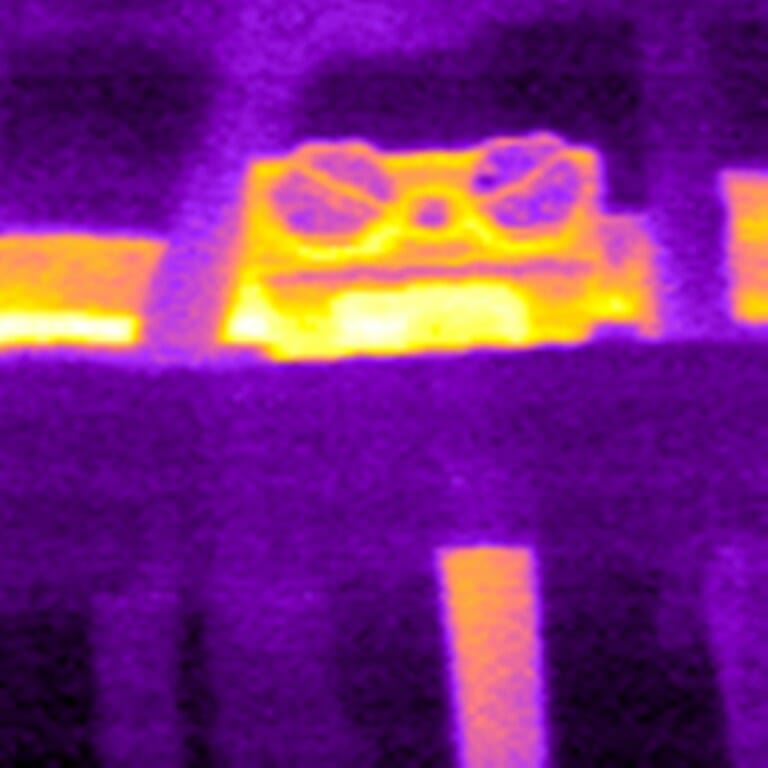

Infrared Scanning

Buss Plug that connects wire to a Buss Bar in a breaker

When you open a panel…

…you never know what may be smiling back at you!

Infrared scanning can detect problems such as High Resistance Connections, High Contact Resistance or Overload in Breakers as well as Defective Fuses in Disconnects. These can be discovered before they produce failures.

Abnormalities in Switchgear generate heat. Infrared scanning shows us the heat source to pinpoint so it can be repaired.

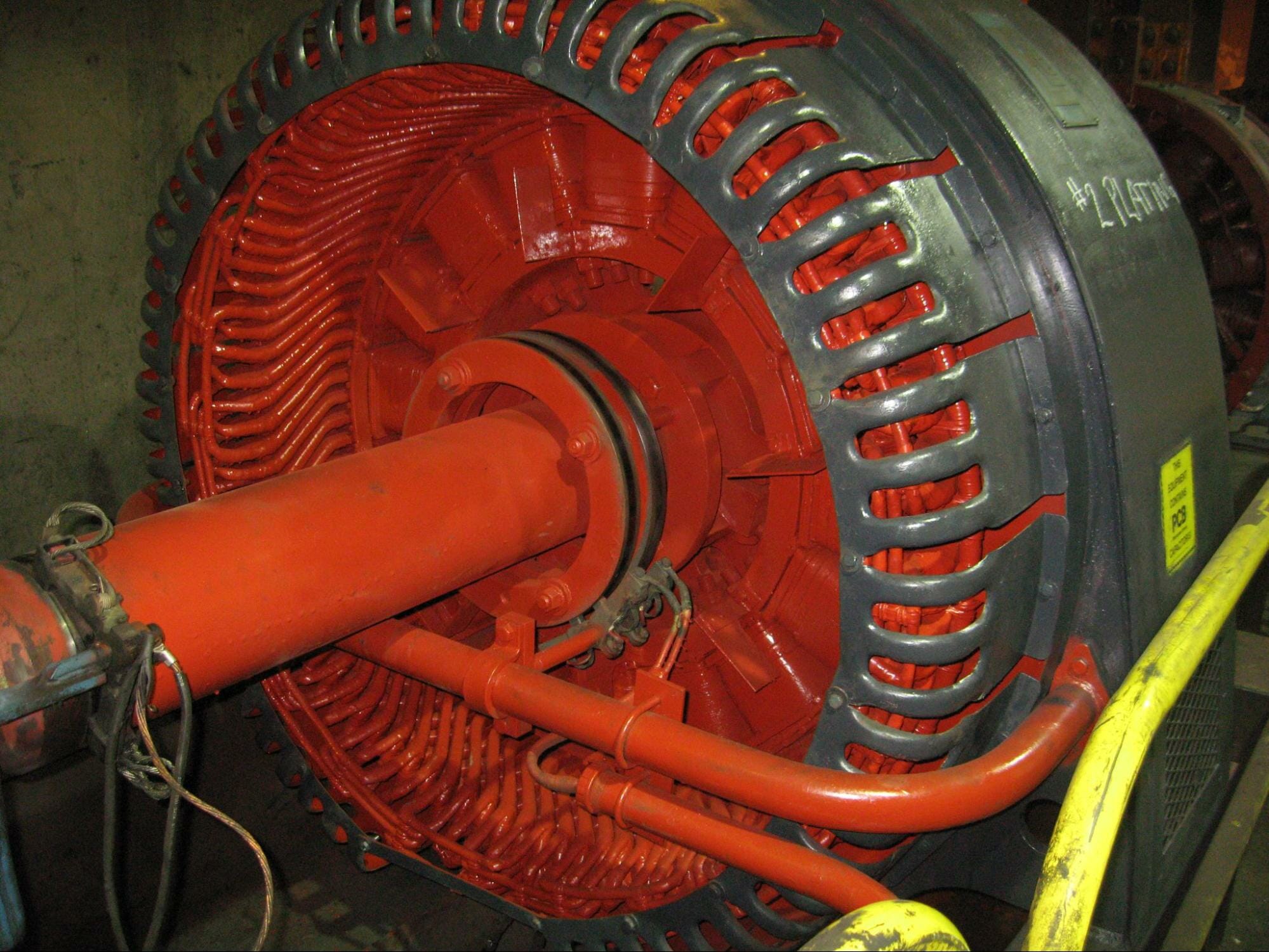

Electric Motor Testing

Types of motor testing on-site include resistance testing and Polarization index testing. This testing checks the condition of the windings. Both the polarization index and megger tests can uncover weak insulation in a winding.

These are tools to be compared over time to make the correct decision when considering removing a motor for a condition. Sometimes, electric motors can be tested from the panel leads instead of at the motor. This makes it so the technicians do not have to disconnect and retape leads at the motor.

Dry Ice Blasting

For industrial motors, generators, and switchgear

Before

After

Dry ice blasting your motor can be performed at your facility. When completed on larger motors, the results are similar to a recondition. Dry Ice blasting also has a quicker turnaround than in-shop repair.

The on-site service saves you the time and expense of removal, shipment both ways, re-installation, and alignment of your motor.

In some cases, Dry ice blasting can also be performed on switchgear as part of substation maintenance.

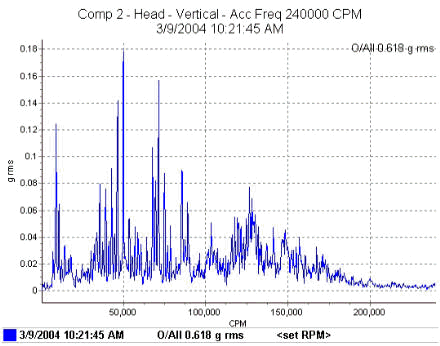

Vibration Analysis

For motors, pumps, and gearboxes

Vibration Analysis is used to uncover problems that a motor, pump, or gearbox may have before it causes a catastrophic failure.

These problems include:

- Bearing issues

- Misalignment

- Unbalance

- Soft foot

- Mechanical Looseness.

- Cavitation, and more

The sooner one of these symptoms is discovered, the quicker it can be repaired and the less damage it may cause.

Vibration readings are taken while the equipment is in operation so there is minimal downtime. Some issues discovered may be rectified on-site, maintaining normal operation.

If discovered early, many issues can be efficiently repaired before creating a catastrophic failure. For example, the misalignment of a shaft, if left uncorrected, could create a bearing failure which could then produce a winding failure. Both of these issues would create considerably more cost and downtime than if the misalignment were initially corrected upon discovery during a preventive maintenance vibration analysis.

Laser Alignment

Motor to Pump Laser Alignment

Correct installation of a motor requires that it be aligned properly with the driven load. Misalignment can eventually lead to high vibration, bearing problems, increased energy consumption, excessive coupling wear, or even a broken shaft. Misalignment can also result in poor-quality parts or even rejected ones. Laser alignment is the solution.

Lasers monitor and test the alignment of motors to a precision that far exceeds other methods. The process can detect the smallest misalignment of components, preventing later catastrophic breakdowns or machine failure.

Keeping all the parts of your motors working in harmony ensures your company will maintain smooth and efficient operations.

Primary Injection Testing

Primary Injection Testing (In Shop and On-Site): Tests the breaker to make sure it trips within the manufacturer’s parameters. If it does not trip when necessary, Current (or Power) will go through the line when it shouldn’t and possibly damage something else. When a breaker is working properly it opens the circuit to prevent this from happening.

Medium Voltage Starter

Breaker Retrofitting

Retrofitting a breaker replaces old or defective trip units in the breaker. This is done in our shop. It is one of the reasons why we have developed a strong used equipment network. When a breaker issue is suspected, we try to find a spare unit through our network as soon as possible. After changing out the breaker, we can work on replacing the trip units in your breaker at our shop, and your company can get back valuable production time.